Machen Sie es sich einfach und gehen Sie auf Nummer sicher mit dem Endoprime System

Die Aufbereitung flexibler Endoskope stellt hohe personelle und organisatorische Anforderungen an endoskopische Fachabteilungen und Aufbereitungseinheiten für Medizinprodukte. Zeitdruck, komplexe Abläufe, aufwendige Schulungen und ergonomische Belastungen erschweren die konsequente Einhaltung aller Hygienerichtlinien für das Fachpersonal.

Wie das Robert-Koch-Institut in seiner amtlichen Mitteilung „Anlage 8: Anforderungen an die Hygiene bei der Aufbereitung thermolabiler Endoskope“ festhält, sind die meisten endoskopiebedingten Infektionen weiterhin auf die Nichteinhaltung bestehender Richtlinien und damit auch auf den menschlichen Faktor zurückzuführen.

Eine automatisierte Reinigung anstelle der manuellen Bürstenreinigung minimiert diese Risiken und Fehlerquellen deutlich. Sie sorgt für reproduzierbare Ergebnisse, entlastet das Personal und erhöht gleichzeitig die Prozesssicherheit für die Verantwortlichen. Aus diesem Grund haben wir Endoprime entwickelt, für einen standardisierten Reinigungsprozess, der mehr Hygiene, Effizienz und Sicherheit im Alltag der Aufbereitung gewährleistet.

Das Problem

Die Aufbereitung flexibler Endoskope stellt das Fachpersonal täglich vor große Herausforderungen. Die manuelle Bürstenreinigung ist arbeitsintensiv, zeitaufwendig und schwer zu validieren.

Die engen Arbeitskanäle sowie Anschlüsse, Abzweigungen und Materialübergänge sind mit Bürsten oft kaum erreichbar.

Doch nur eine rückstandslose Aufbereitung ermöglicht eine sichere maschinelle Reinigung, Desinfektion und bei Bedarf auch Sterilisation. Unachtsames Arbeiten kann zu Rückständen oder Beschädigungen der inneren Kanäle führen und das Risiko von Kreuzkontaminationen erhöhen.

Die Lösung

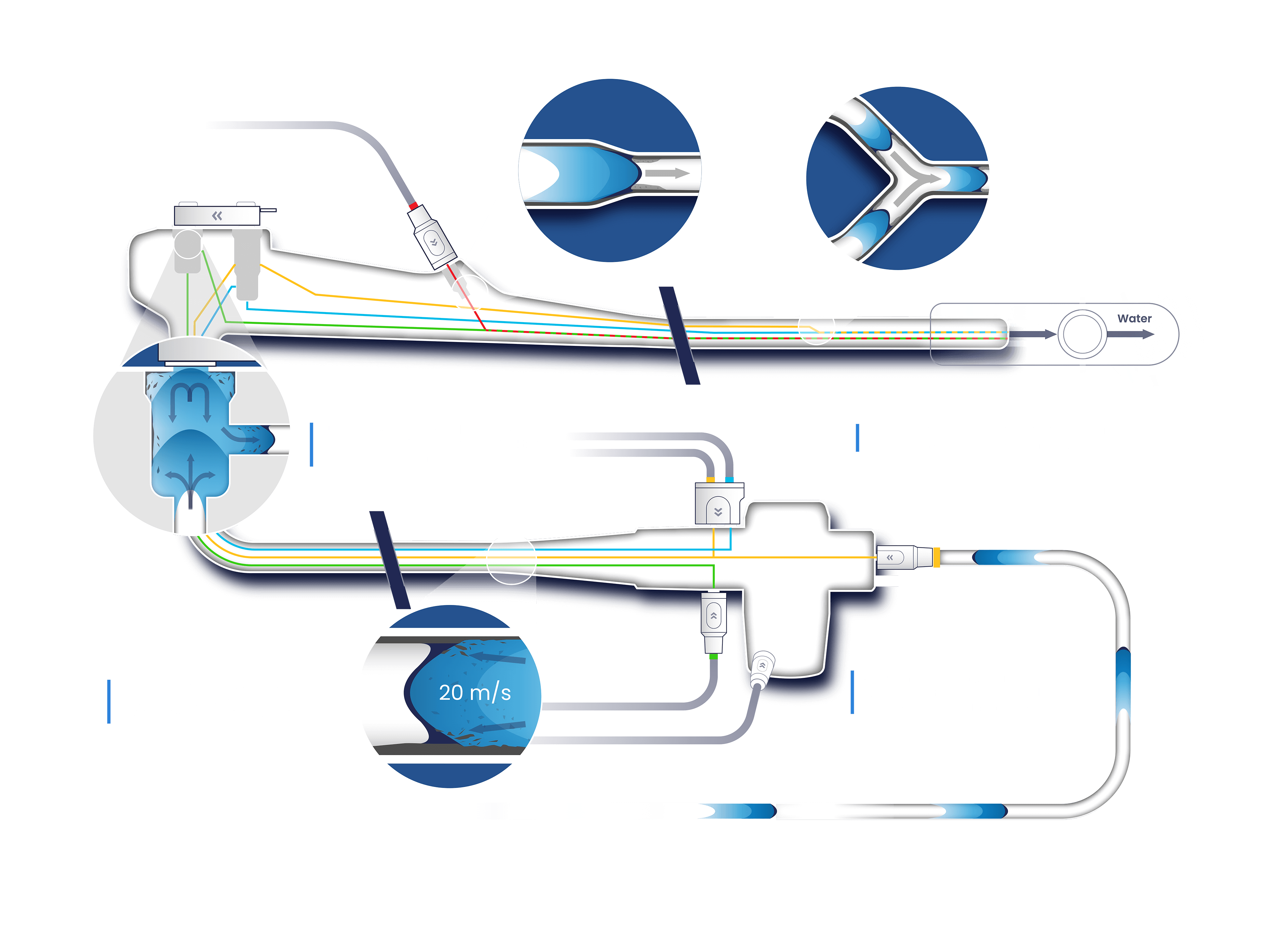

Durch den Einsatz von Comprex® werden Ablagerungen wie angetrocknetes Blut, Gewebereste und Biofilme zuverlässig aus den Endoskopkanälen entfernt. Der Impulsspülprozess aus Wasser und Luft arbeitet dabei deutlich effizienter und hygienischer als herkömmliche manuelle Bürstenreinigungen – ganz ohne Verbrauchsmaterial oder Prozesschemie. Auch künstlich zugeführte Verschmutzungen wie Gleit- und Kontrastmittel, Blutstiller oder Farbmarkierer werden sicher entfernt.

Das System lässt sich nahtlos in bestehende Arbeitsabläufe und Infrastrukturen integrieren. Anstatt intensiv zu bürsten, müssen lediglich die Endoskopanschlüsse über einen Verteiler an das Endoprime System angeschlossen werden.

Das Ergebnis

Mit Endoprime bieten wir eine automatisierte, validierbare und reproduzierbare Lösung für die sichere Aufbereitung flexibler Endoskope. Der gesamte Reinigungsprozess wird digital erfasst und ermöglicht so eine lückenlose Dokumentation. Über Barcode oder RFID werden sowohl das Endoskop als auch das Personal registriert. Gleichzeitig passt das System die Reinigungsleistung automatisch und individuell an die Kanalgrößen, Längen und Abzweigungen der Endoskope an.

Durch die Reinigung aller Kanäle mit Frischwasser, den separierten Reinigungsaustrag und den integrierten Dichtigkeitstest werden nachweislich bessere Reinigungsergebnisse erzielt. Der Verteiler sowie das Endoskop können anschließend wie gewohnt in der maschinellen Reinigung und Desinfektion weiter aufbereitet werden.

Wir stehen hinter der Endoprime Innovation

Die Comprex® Medical GmbH ist ein Unternehmen der Hammann GmbH und setzt das bewährte Comprex® Verfahren speziell für die Medizinbranche ein. Mit Van Vliet Healthcare steht ein erfahrener Partner zur Seite, der maßgeblich die Entwicklung, Produktion und den Vertrieb des Systems organisiert. Die enge Zusammenarbeit beider Unternehmen stellt einen wichtigen Schritt dar, um die internationale Skalierung von Endoprime voranzutreiben und dabei höchste Qualitätsstandards sowie maximale Kundenzufriedenheit sicherzustellen.

Schnell, automatisiert, nachhaltig

Bis zu 100x stärker

Bis zu 90% geringer

Bis zu 10x schneller

Ohne Chemie

und Bürsten

Log-Reduktion

Mit der automatisierten Endoprime Reinigung wird eine Log-Reduktion von bis zu 4 Stufen erreicht und führt nach der maschinellen Reinigung und Desinfektion nach (DIN EN ISO 15883) zu einer gesamten Log-Reduktion von bis zu 13 Stufen.

Damit wird ein reproduzierbarer und höherer Hygienestandard als mit der bisherigen manuellen Bürstenreinigung erreicht.

Die Reinigungsleistung von Endoprime wurde nach der Norm EN ISO 15883-4 / EN ISO 15883-5 ohne Chemikalien oder Reinigungsmittel getestet.

Die Testergebnisse bestätigen die herausragende Reinigungsleistung von Endoprime und zeigen,

dass die gleichen Reinigungsstandards wie bei der maschinellen Reinigung (Vor-Desinfektion) erfüllt werden:

a) Entfernung von Geobacillus stearothermophilus (ATCC 7953) Sporen gemäß EN ISO 15883-4:2019, B.3.4

b) Bewertung der Reinigungseffizienz gemäß EN ISO 15883-4:2019, 6.11 durch Protein und Gesamtorganischen Kohlenstoff (TOC)

Nachweis nach Kontamination des Endoskops gemäß EN ISO 15883-5

Automatisierter Reinigungsprozess in nur 5 Minuten

- Einfache Integration in bestehende Arbeitsabläufe und Umgebungen – wandmontiert oder stehend

- Bedienerfreundliche Anleitung unterstützt die einfache Anwendung und Mitarbeiterschulung

- Alle Kanäle werden mit Frischwasser gereinigt – inklusive integriertem Dichtigkeitstest

- Das Endoskop wird während der Reinigung in einem befüllten Reinigungsbecken gelagert

- Trennung des Abflusses der inneren Endoskopkanäle zur Verbesserung der Hygiene im Waschbecken

- Digitale Dokumentation des Prozesses und der Ergebnisse

- Für die anspruchsvolle Reinigung aller flexiblen Endoskope sowie von Duodenoskopen und Endosono-Endoskopen geeignet

Bewährter Ablauf - noch effizienter und nutzerfreundlicher

Die bisherige Vorreinigung im Untersuchungsraum bleibt bestehen – inklusive Wischreinigung der äußeren Flächen und der ersten Spülung der inneren Kanäle.

Einfache Benutzer- und Endoskop-Registrierung über RFID oder Barcode direkt am Endoprime System.

Verbinden aller Endoskop-Anschlüsse mit dem Endoprime Verteiler, inklusive Dichtigkeitstest. Der Verteiler ist mit allen handelsüblichen Adaptern der verschiedenen Hersteller kompatibel.

Verbinden des distalen Endes mit dem Abflussadapter für einen separierten Austrag und verbesserte Hygiene. Das Endoskop wird während der Reinigung in einem befüllten Waschbecken gelagert.

Automatisierte Reinigung aller Kanäle mit dem Comprex® Impulsspülverfahren. Digitale Dokumentation aller Reinigungsparameter und Ergebnisse.

Anschließend wird das Endoskop wie gewohnt in der maschinellen Reinigung und Desinfektion aufbereitet. Der Endoprime Verteiler kann ebenfalls täglich in der maschinellen Reinigung und Desinfektion aufbereitet werden.

Profitieren Sie jetzt von dem Endoprime System!

Die Aufbereitung medizinischer Instrumente wie flexibler Endoskope erfordert höchste Standards in Hygiene, Validierung und Prozesssicherheit. Mit der Expertise von Van Vliet Healthcare bieten wir eine Reinigungslösung, die medizinischen Standards entspricht, validierbar ist und zuverlässig sichere Ergebnisse liefert.

Starke Vorteile für Ihre Aufbereitungsprozesse - mit Endoprime und Comprex® reinigen Sie einfach effizienter

Reinigung nur mit Luft und Wasser – keine Risiken für Mensch, Material oder Umwelt durch austretende Reinigerdämpfe.

Die Nutzer- und Endoskop-Registrierung per RFID oder Barcode ermöglicht die automatische Dokumentation der Reinigungsergebnisse. Über eine WLAN- oder USB-Schnittstelle können die Daten übermittelt werden.

Es besteht weder Spritzgefahr noch ein Kontaminationsrisiko, während klare visuelle Anweisungen eine einfache Bedienung und schnelle Einschulung ermöglichen. Gleichzeitig sorgt die automatische Auswahl der passenden Reinigungsparameter für einen reibungslosen Ablauf.

Verwenden Sie Ihre vorhandene räumliche Ausstattung weiter - einfach integrieren, direkt einsetzen

Das Gerät ist 25 cm breit, 35 cm hoch und 20 cm tief und kann mit einem Gewicht von 4,5 kg stehend oder hängend neben vorhandenen Reinigungsbecken installiert werden.

Es werden lediglich ein Stromanschluss, ein Wasseranschluss mit 2 bar und ein Druckluftanschluss mit 4 bar benötigt.

Der Comprex®-Impulsdruck von ca. 3 bar ist während der Reinigung ungefährlich für die Endoskopkanäle und liegt effektiv unterhalb des Drucks handelsüblicher maschineller Spülvorgänge.

Mit Comprex® lassen sich Ablagerungen wie angetrocknetes Blut, Gewebereste, Biofilme, sowie künstlich hinzugefügte Verschmutzungen wie Gleit- und Kontrastmittel effektiv aus den Kanälen flexibler Endoskope entfernen. So wird im Anschluss eine sichere maschinelle Reinigung und Desinfektion im RDG-E gewährleistet. Die Druckbelastung der Endoskopkanäle während des Comprex® Prozesses entspricht dabei den üblichen Spülvorgängen im RDG-E, sodass das System sicher und materialschonend eingesetzt werden kann.

Durch die automatisierte Reinigung aller Kanäle mit individuell angepassten Reinigungsparametern lassen sich alle handelsüblichen Endoskope – unabhängig von Typ oder Hersteller – zuverlässig und reproduzierbar reinigen. Spezialisierte Reinigungsprogramme entfernen selbst hartnäckige Rückstände in komplexen Strukturen, wie in Anschlüssen, Abzweigungen oder schwer zugänglichen Schattenfugen, rückstandslos und validierbar. Der gesamte Reinigungsprozess einschließlich der zuständigen Fachkraft, des Endoskops und aller Reinigungsparameter wird im Anschluss digital dokumentiert.

Die Anwendung ist einfach: Das Endoskop wird über RFID oder QR-Code identifiziert, die passenden Adapter angeschlossen

und das System wählt automatisch die optimalen Reinigungsparameter aus.

Klinikum Hochsauerland

Bürstenlose Reinigung von PTFE-Prüfkörpern als Surrogat von Endoskopkanälen

Hygiene & Medizin | Volume 45 | 12/2020

Aufbereitung von Endoskopkanälen – Substitution der manuellen Vorreinigung durch das Impulsspülverfahren Comprex®

Hygiene & Medizin, Ausgabe: 03/2017

Eine neue Technik zur Endoskop-Aufbereitung – das Comprex® Verfahren

DeviceMed, Ausgabe: 05/2008